More quickly adjusting supply/demand balance by visualizing data on inventory at overseas sites

- Global 3PL

- Aerospace

Aeronautics components manufacturers

Background

The most critical aspect of logistics for the maintenance of aircraft is securing the proper balance of supply and demand. If additional stock of components runs out, this can cause aircraft to be grounded on the tarmac while new ones are procured. By contrast, maintaining vast stocks of inventory leads to steep maintenance costs. Pursuing proper maintenance-related logistics involves:

1. Rapid assessment of inventory at multiple sites and estimating inventory needed

2. Adjusting inventory positioning to stably cope with rapid spikes in demand

3. Reducing liabilities associated with returns, defects, and long-term inventory

and other issues.

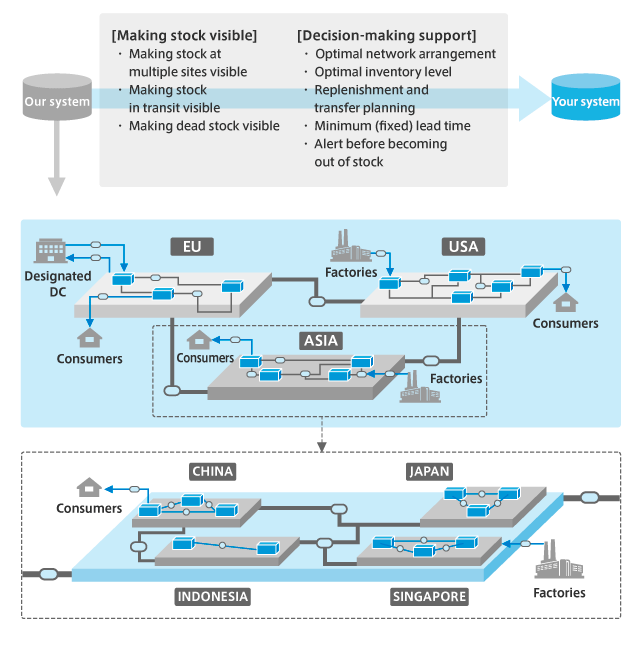

Proposals

We take a global stance to integrating systems and providing new services. This allows for integrating data from territories as diverse as the EU, Asia, and the USA on a global level and managing them through a unified system. This has allowed us to achieve the visualization of a multi-point inventory system, cargo packing and shipment, and long-term or defective inventory. Through this, we can optimize the allocation of sites and inventory volume, and restock or forward inventory to different sites as needed. This allows for achieving a fixed or minimum lead time. With advances like alerts of out-of-inventory and other details, decision-makers are given timely information they need to render a decision and keep the workflow moving.

Outcome

- When the inventory at a specific site falls below the set minimum due to an unplanned high-volume order, a computation is made based on past dupply/demand data to calculate the inventory required until the next shipment.

- Sites with leeway in future inventory are displayed, and the optimal routes and cost are extrapolated and stakeholders notified. Accurately assessing optimal inventory forwarding flows on a per-product, -time, and -site basis.

- As a result, the client is able to avoid air shipment and prevent unnecessary extra costs. In addition to avoiding chronic out-of-inventory risk and chain reactions resulting therefrom caused by incorrect and subjective forwarding of inventory, the appropriate amount needed is flexibly assessed in advance, eliminating the need for long-term storage while still keeping enough inventory on hand.

- In the event of defective inventory at a specific site, products in the same lot at other sites are held.

- Immediately generating report logs of shipment destinations at all sites for products in same lot

- Browse defective inventory on a per-site, per-product, and per-cause basis

- Advising each site on products with potential long-term inventory risk based on supply/demand forecasts

- This in turn reduces opportunity loss and cuts down on unnecessary storage expenses

Eliminating under/over-inventory

Smooth handling of defects and shortage of inventory

Rapidly assessing long-term, defective, and returned inventory across multiple sites

- HOME

- Company Information

- Past Projects

- More quickly adjusting supply/demand balance by visualizing data on inventory at overseas sites